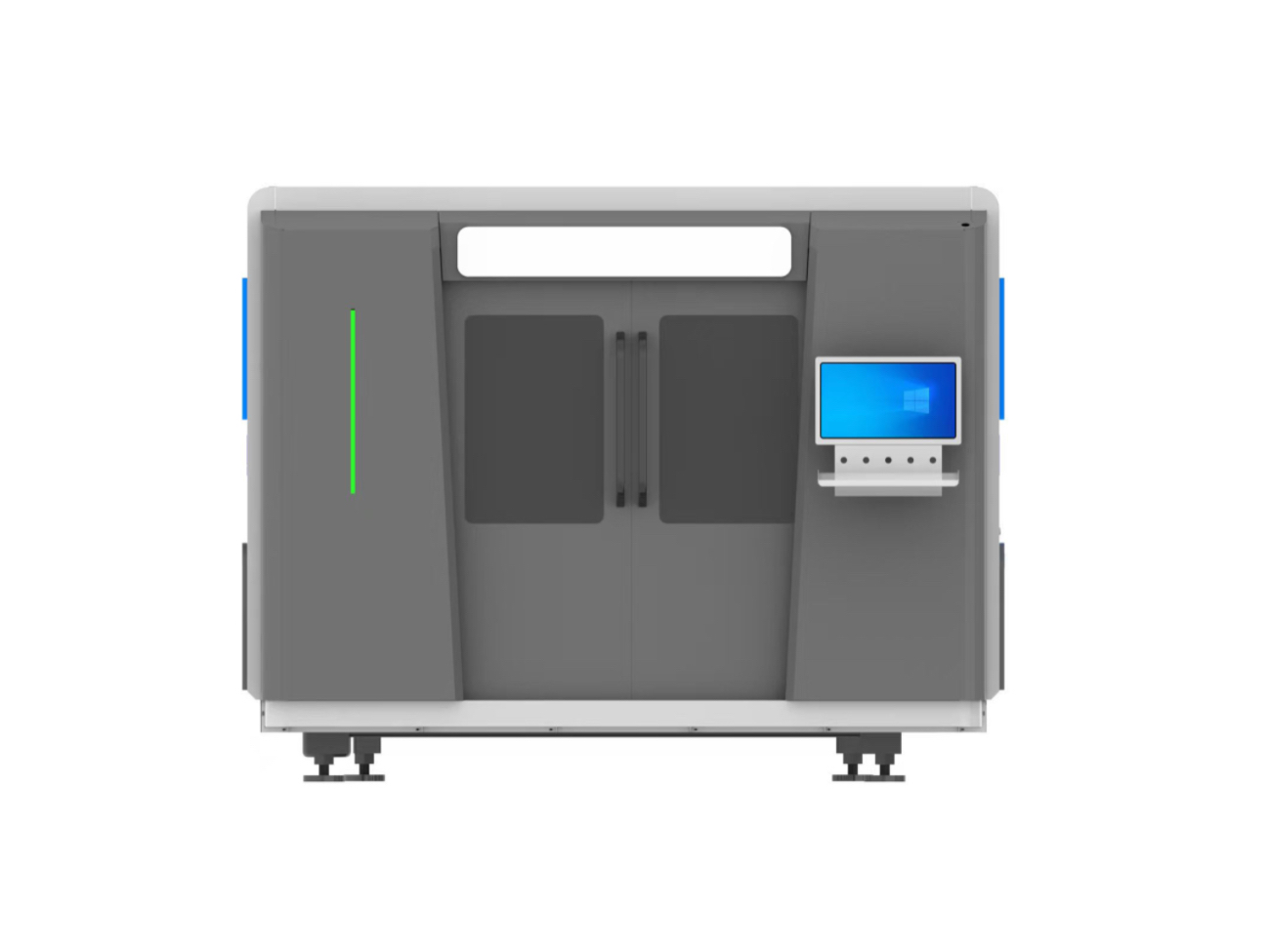

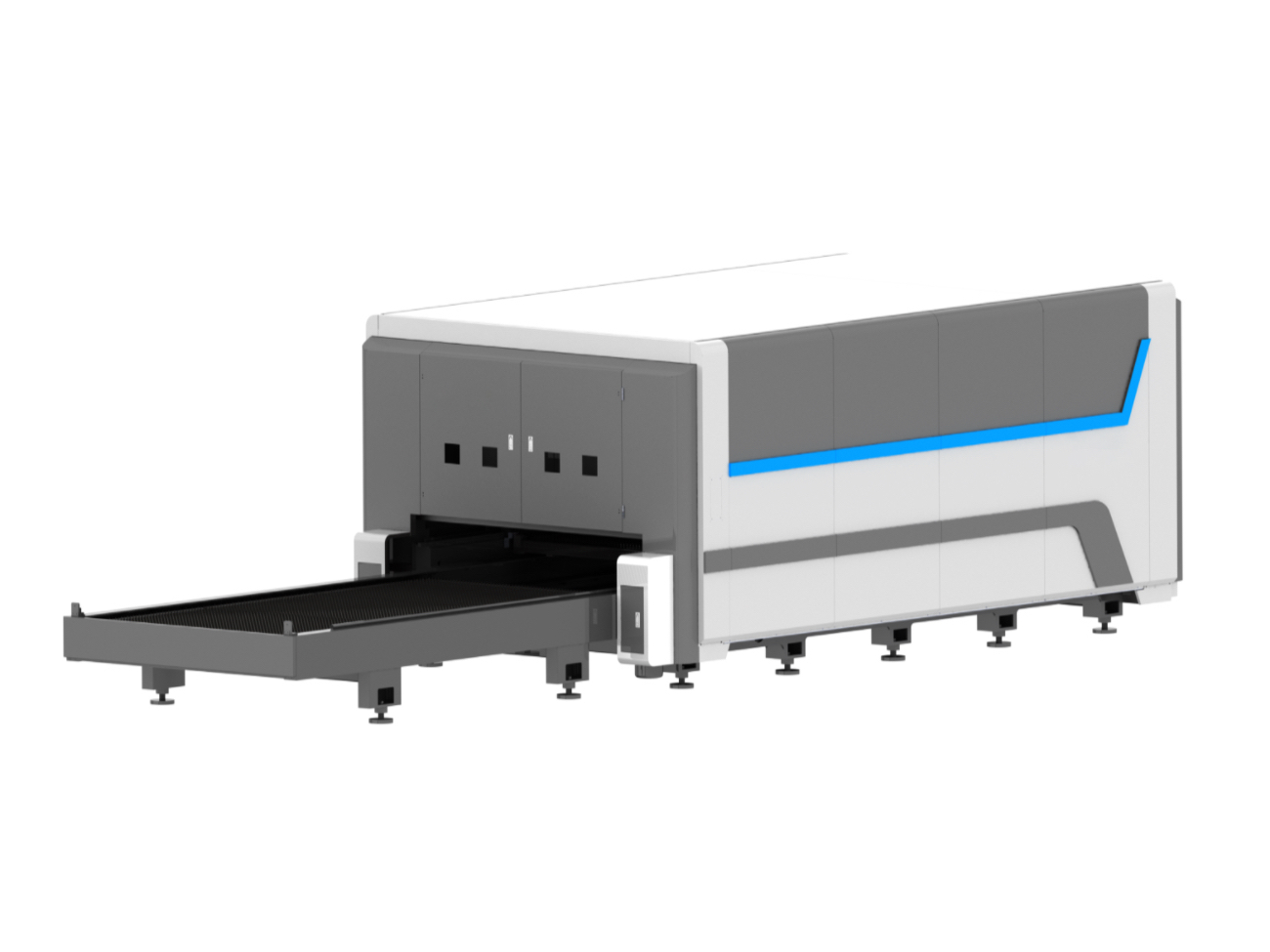

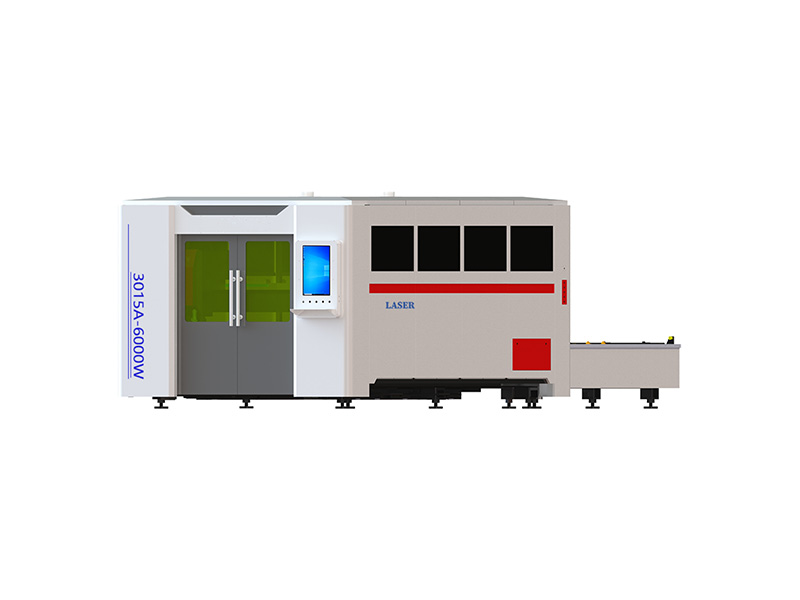

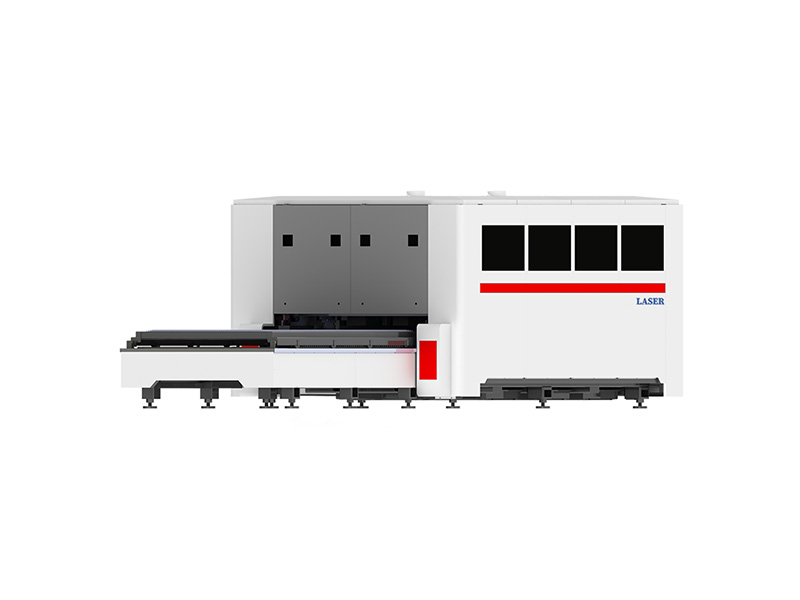

Fully Enclosed Interchangeable High Power Fiber Laser Cutting Machine

Get a free quoteIt features a dual interchangeable working table system and a 360° comprehensive protection device, creating a fully enclosed chamber that effectively controls smoke and ensures a clean working environment. This design allows the equipment to maintain exceptional cutting stability at high power and high-speed operations, elevating its product positioning to higher standards.

Our own Sheet Metal Workshop :

From Cutting-Bending-Welding, control the quality at the source,Ensure the weight & precision of the bed!

12mm Insertion Plate welding Bed Stability Increased by 20% :

Lattice transition austenite stable bed ; 630 °C Annealed Bed ; 24 hour stress relief !

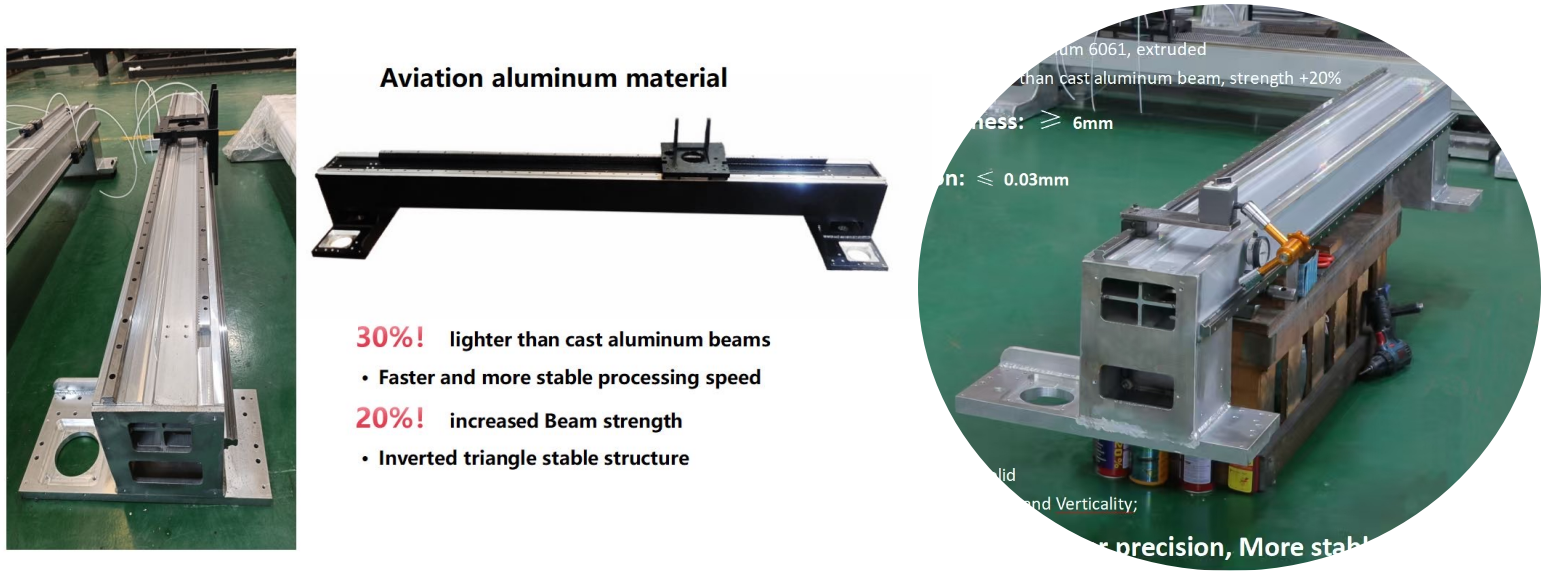

6061 aerospace aluminum, extruded crossbeam -30% ighter than cast aluminum beam, strength +20%

Wall Thickness:>6mm,Precision:< 0.03mm

Solid Guide surface : ensuring Parallelism and Verticality;

Faster speed, Higher precision, More stable!

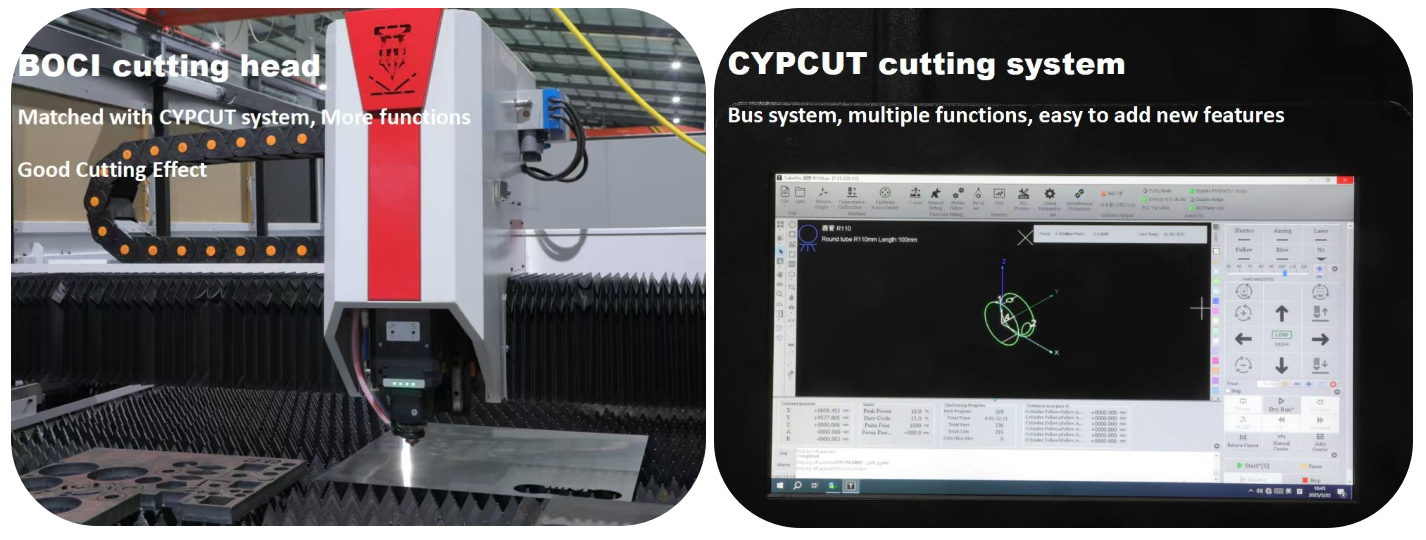

Bocl cutting head

Matched with CYPCUT system,Bus system, multiple functions, easy to add new features

More funotions,Good Cutting Effect

Taiwan JT Rack, original ; Taiwan Dix Guide Rail, original. Accuracy≤0.03mm

Motor and Reducer integrated :Cut the circle, More round ! Durable -Stable-High precision

Gear accuracy < 0.05;Structure: Flange output, precision <0.02mm

Built-In laser source(≤6kw)

Waste oil collection, Independent cabinet,More beautiful and clean ;

Anti-collision sensor

Optional

Dust collector,Air compressor, voltage stabilizer

Optional

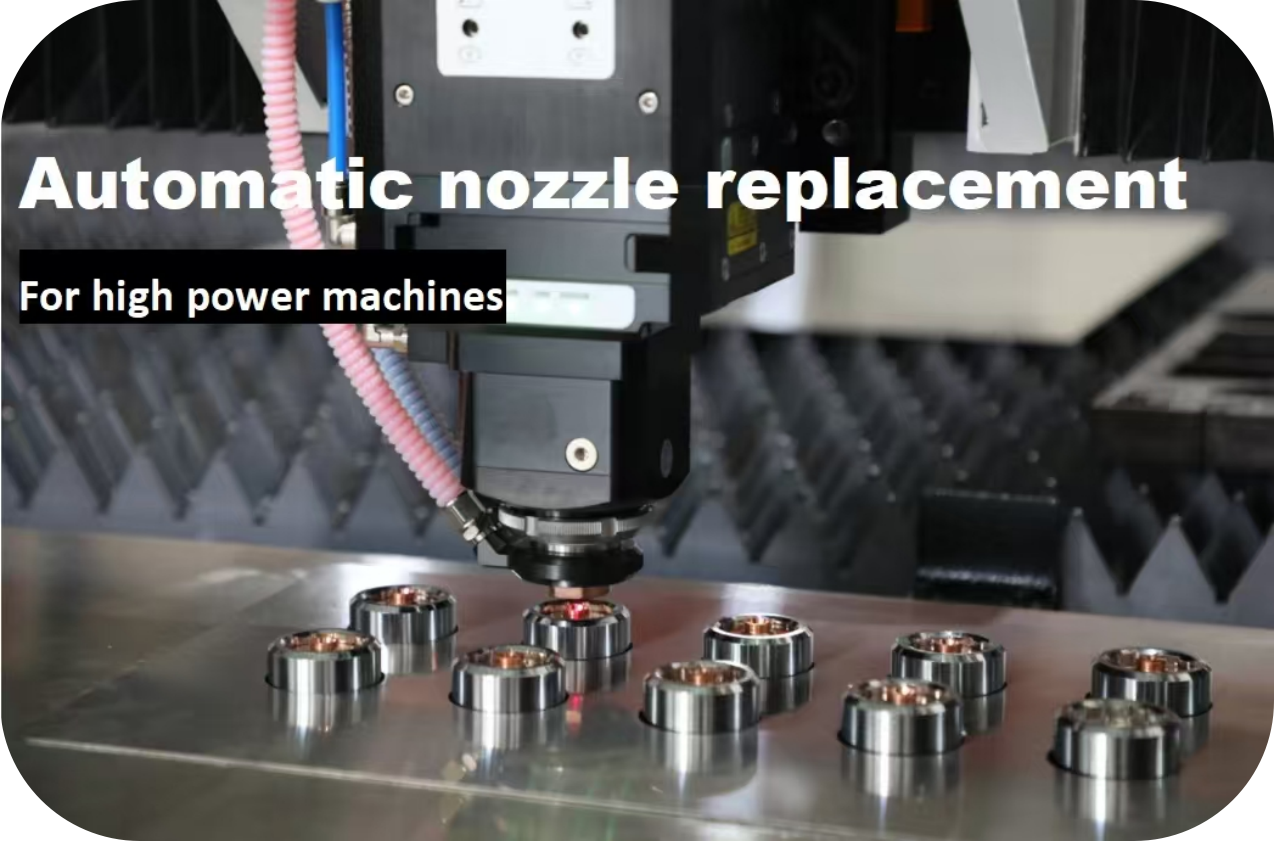

Automatic nozzle replacement:For high power machines

Robust Main Frame Welding:

Utilizing a mixed welding structure of profiles and plates, with over 60% of the structure comprised of sheet metal. This design provides a stable welding process, flexibility in design, ease of manufacturing, rational structural arrangement, strong rigidity, excellent torque resistance, and minimal internal defects, making it a crucial welding method for black metal materials.

Stress Relief Annealing:

To eliminate material stress resulting from welding, a large fuel-fired annealing furnace is employed, subjecting multiple main frames to 600-degree annealing simultaneously. The furnace maintains stable and uniform temperatures, and electronic monitoring ensures thorough stress removal from the welding process, guaranteeing product quality that cannot be achieved with typical small electric furnaces, which often result in uneven temperature and incomplete stress elimination.

Precision Machining:

High-precision surfaces, such as the guide rails and racks of the machine bed, undergo machining with a 5-axis CNC machining center to obtain a high-quality installation base, ensuring cutting precision.

High-Strength Aerospace Aluminum Beam:

Featuring a unique honeycomb-shaped patented design, this beam offers a large cross-section, lightweight construction, high strength, excellent precision, and dynamic responsiveness. It is suitable for high-speed, high-response, and high-performance laser cutting.

Top-Tier Laser Source:

The machine is equipped with an internationally renowned laser source, and it features a mobile gantry structure and an overall surrounding enclosure that facilitates efficient smoke and dust removal during cutting. This ensures long-lasting stability, safety, and environmental friendliness.

Video

Features & Advantages

Automatic Focus Laser Cutting Head:

No manual focus adjustment is needed as the software automatically adjusts the focusing lens and controls the vertical movement, enabling automatic piercing and cutting of different thicknesses of sheet metal. The software remembers the focal lengths for various materials, simplifying operation.

Long Service Life:

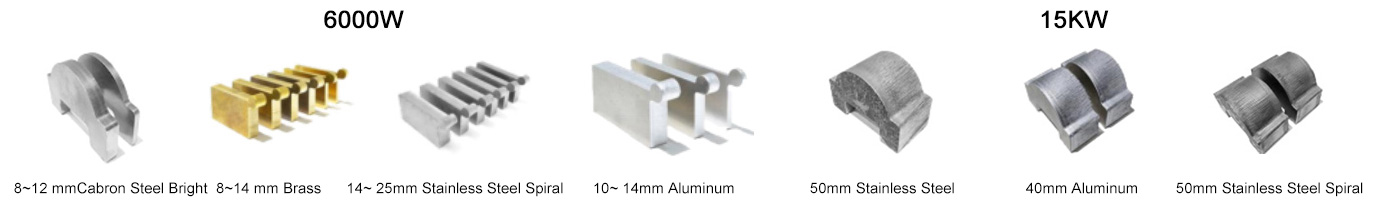

Tailored for users, an air cutting process database is provided, suitable for various metal materials, including carbon steel, aluminum, copper, and especially stainless steel, with a cutting thickness of up to 90mm.

Leading Brand FSCUT Laser Cutting Control System:

Featuring a user-friendly human-machine interface and wireless handheld controller.

Servo Drive System:

The motion mechanism employs gear racks, linear guide rails, and other transmissions, along with direct linear guide rail guidance, ensuring high speed, high precision, and high performance of the equipment.

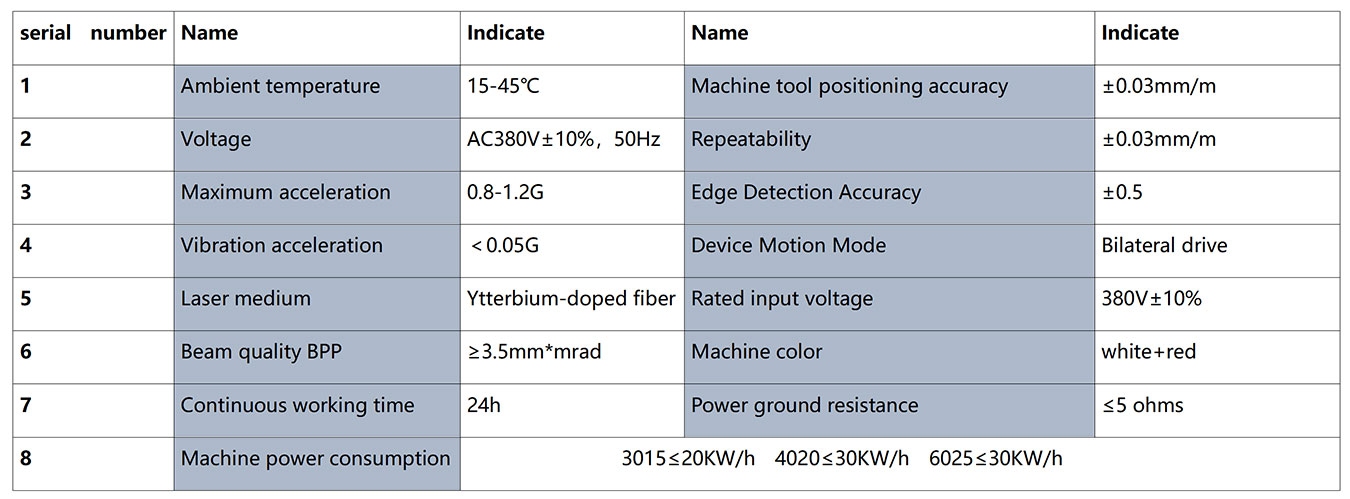

Technical Parameter

Application

Our equipment finds extensive use in various industries, including electromechanical equipment, sheet metal processing, electrical enclosures, stainless steel products, kitchen and bathroom fixtures, lighting fixtures, jewelry, automotive components, eyewear, hardware tools, advertising signage, and interior decoration. It is also widely applied in mechanical processing fields such as dust collector manufacturing, office furniture production, stainless steel sheet metal processing, lighting fixture manufacturing, stair handrail manufacturing, and the elevator industry.

Production Facility

Fully enclosed interchangeable high power fiber laser cutting machine

Fully enclosed interchangeable high power fiber laser cutting machine