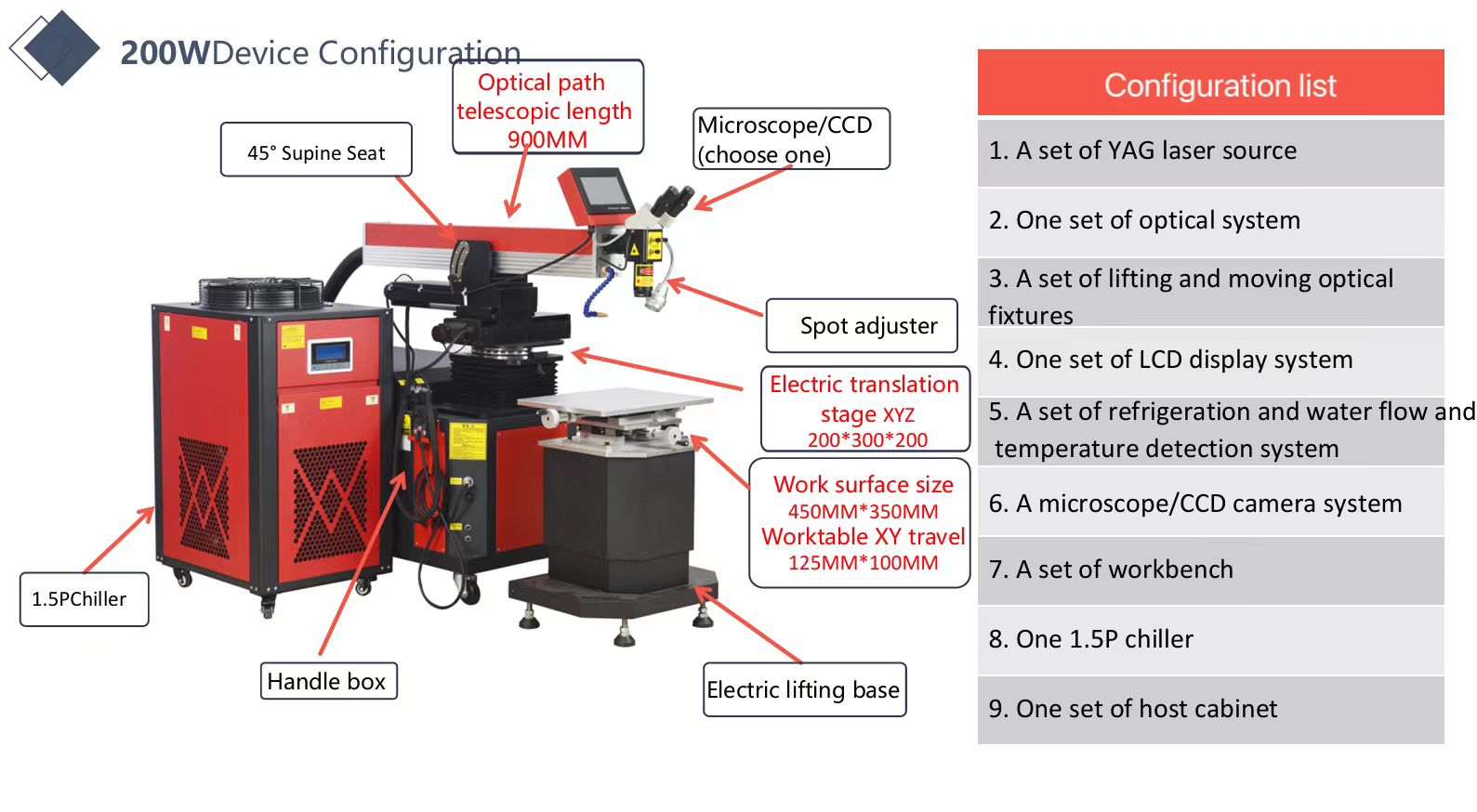

Intergrated boom laser welding machine

Get a free quote1. The core part adopts imported ceramic focusing cavity, which is corrosion resistant, high-temperature-resistant and has a long service life;

2. The world's most advanced automatic shading system is adopted to eliminate eye irritation during work;

3. The laser head can rotate 360°, the super-large work surface is suitable for mold placement, and the electric workbench is raised and lowered;

4. The touch screen interface is simple and convenient to operate;

5. Equipped with a gas protection system, it effectively protects the product from argon protection during the welding process, maintains the original color of the product and ensures the welding quality;

6. The welding energy is high, and it can melt thicker welding wires than general welding machines, and the welding performance is stable.

Video

Technical Parameter

| Laser wavelength | 1064nm | ||

| Reflector in condenser cavity | Ceramic condenser cavity | Double lamp concentrator | Double lamp concentrator |

| Max laser power | 200W | 400W | 600W |

| Rated powef | 8KW | 12KW | 16KW |

| Pluse width | 0.1-10MS | ||

| Spot adjustment range | 0.2-2mm | 0.3-3mm | 0.3-3.5mm |

| Laser frequency | 1-20HZ | 1-30HZ | 1-30HZ |

| Cooling system | 1.5P | 3P | 5P |

| Observing system | CCD or Microscope | ||

| electricity demand | 380V±5V 50Hz/40A 220V±5V 50Hz/60A | 380V±5V 50Hz/40A | 380V±5V 50Hz/40A |

| Overall dimensions/ net weight | Host:1650×550×1230mm | Host:1650×550×1230mm | Host:1650×550×1230mm |

| Chiller:750×500×900mm | Chiller:850×600×1100mm | Chiller:950×700×1300mm | |

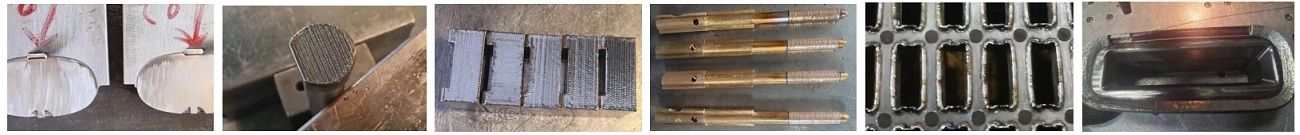

Application

It is suitable for repairing cracks, chipping corners, touching edges and damaged sealing edges of hard materials such as molds, precision injection molding, die casting, stamping, stainless steel, etc.

Production Facility

Intergrated boom laser welding machine

Intergrated boom laser welding machine