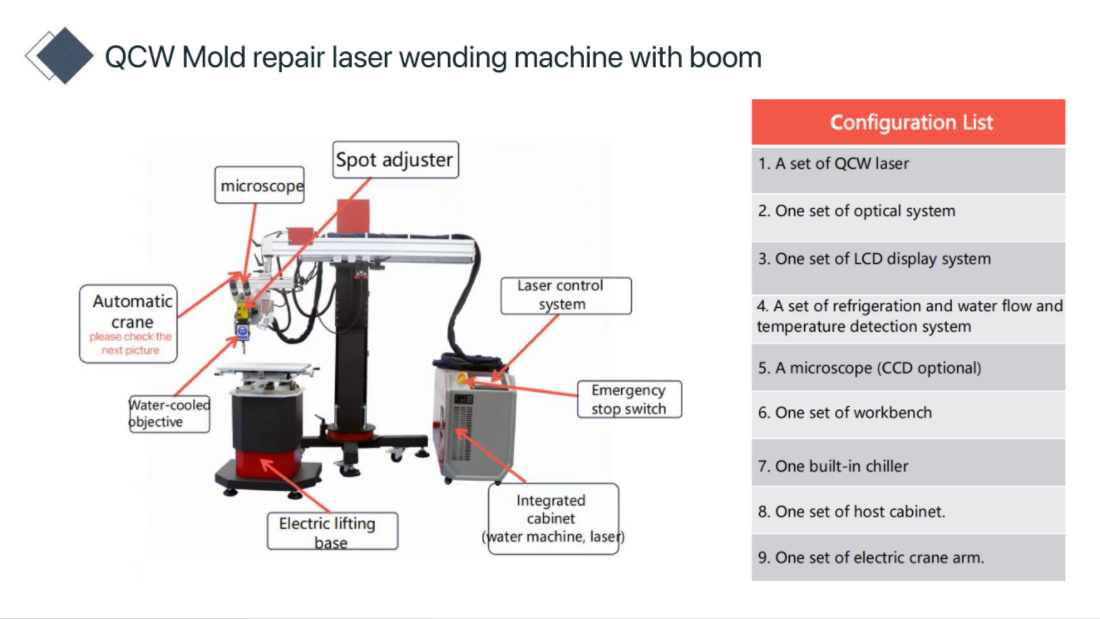

QCW Mold repair laser welding machine

Get a free quote1. Adopt QCW laser; the light spot is stable and energy-saving.Compared with traditional welding machines, there is no need to replace consumables such as lamps.

2. Equipped with a dedicated chiller, which can meet long-term welding and provide better stability;

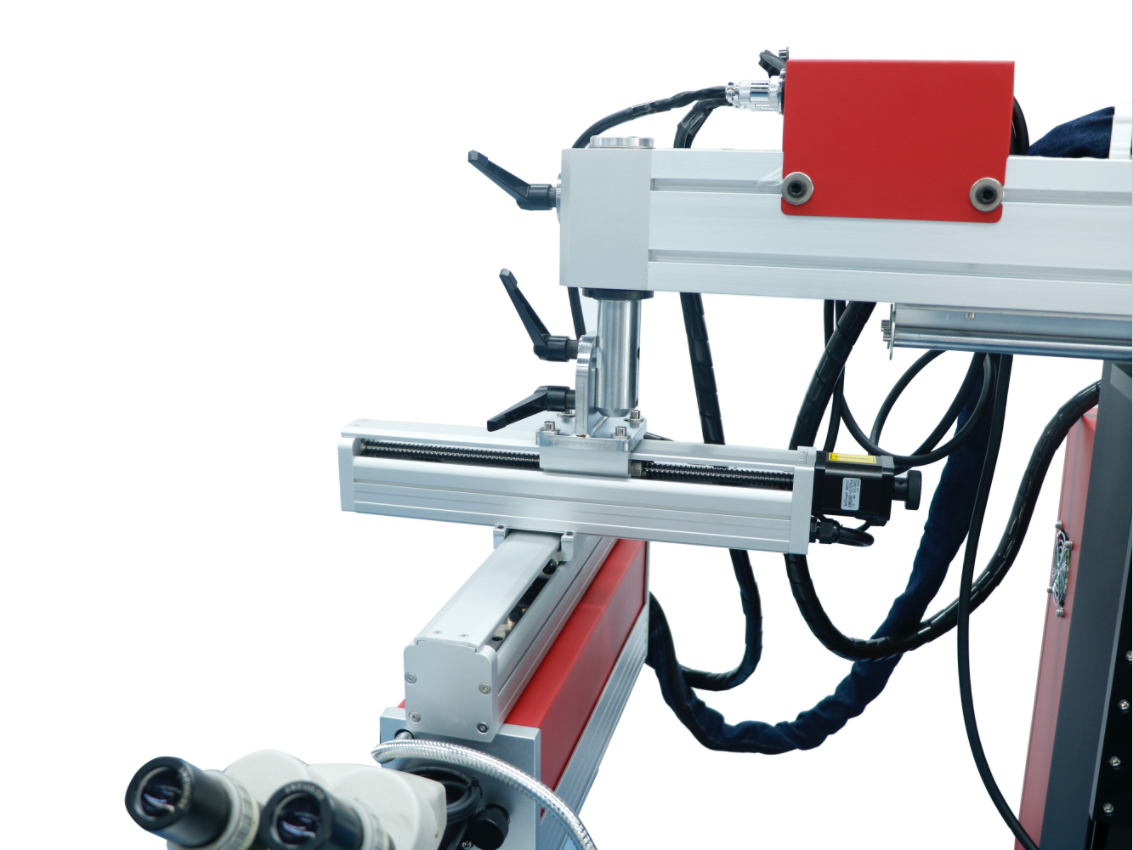

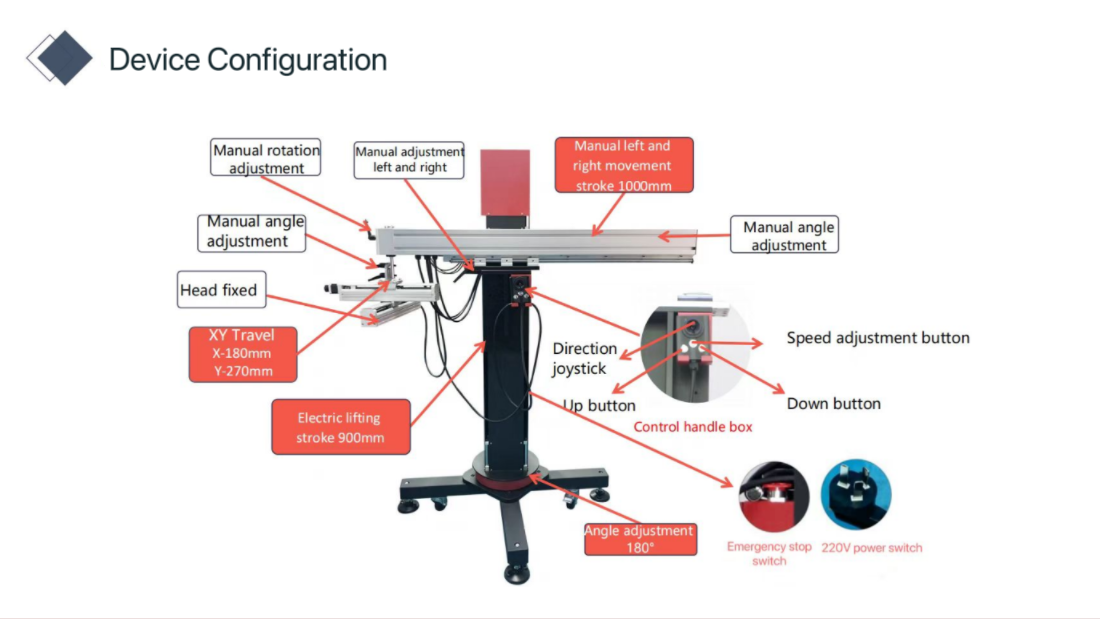

3. Equipped with a three-dimensional load-bearing workbench base with electric lifting, the workbench moves using precision ball screws and high- precision straight guide rails, which are light and flexible, with precise positioning and a load-bearing capacity of up to 100 kg;

4. The laser head can be easily rotated 180 degrees, making it convenient to repair welding on any side;

5. Equipped with a gas protection system, which effectively protects the product from argon gas protection during the welding process, maintains the product's true color and ensures welding quality.

Video

Technical Parameter

| Model | SAN-150W | SAN-300W |

| Laser wavelength | 1064nm | 1064nm |

| Maximum laser power | 150W | 300W |

| Laser fiber length | 10m | |

| Laser frequency | 1-30Hz | 1-30Hz |

| Pulse Width | 1-20ms | 1-20ms |

| Light spot adjustment range | 0.2-3mm | 0.2-5mm |

| Aiming and positioning | Microscope (optional camera system) | Microscope (optional camera system) |

| Chiller cooling power | 0.4P | 0.4P |

| Rated power | 2.5KW | 3KW |

| electricity demand | 220V±5V 50Hz/60A | 220V±5V 50Hz/60A |

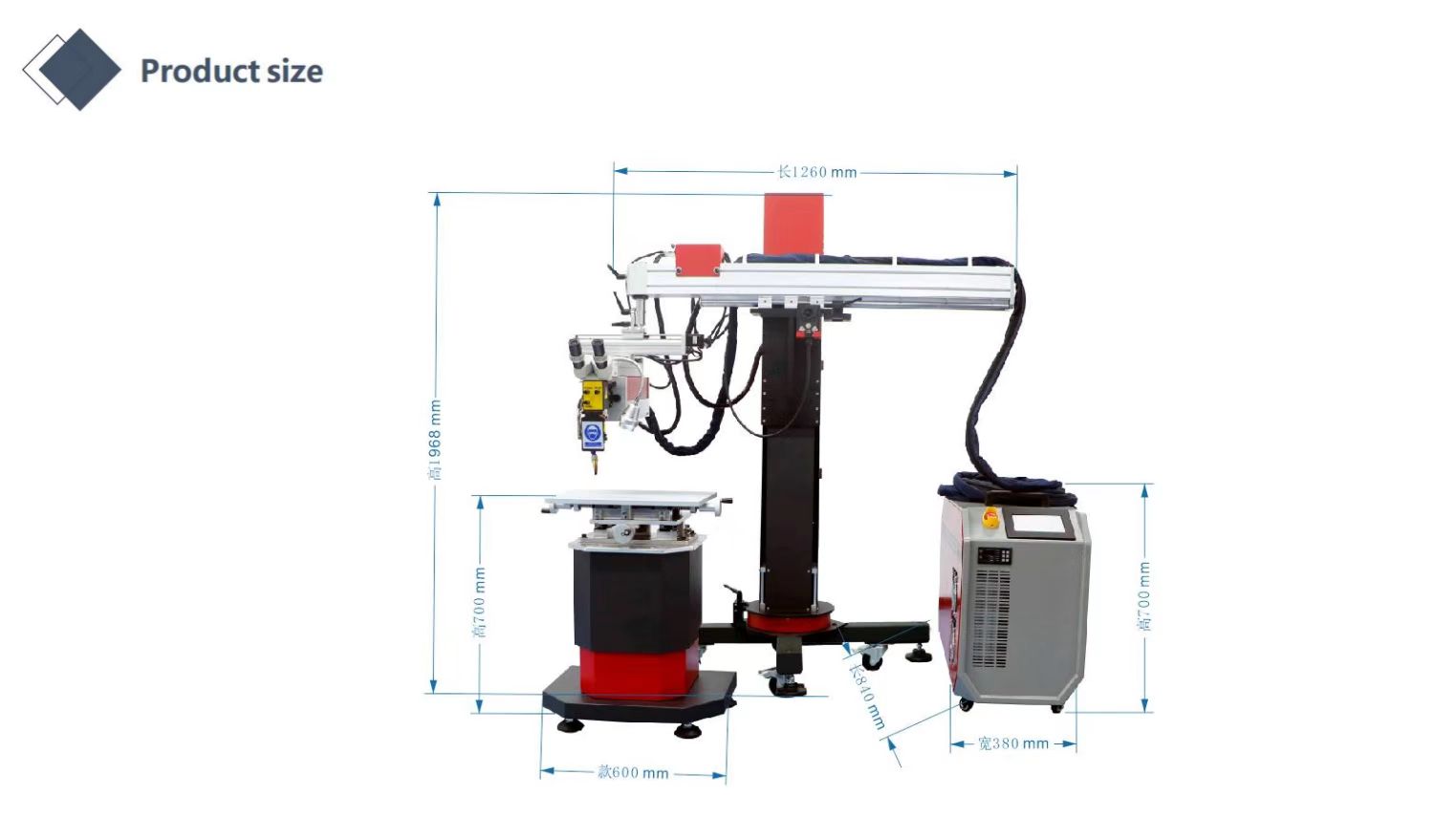

| Overall dimensions/net weight | Host:840*380*700mm | |

| Boom:1260x760x1687mm | ||

| Package size:1450×550×1140mm | ||

| Three-dimensional load-bearing workbench :550×400×700mm | ||

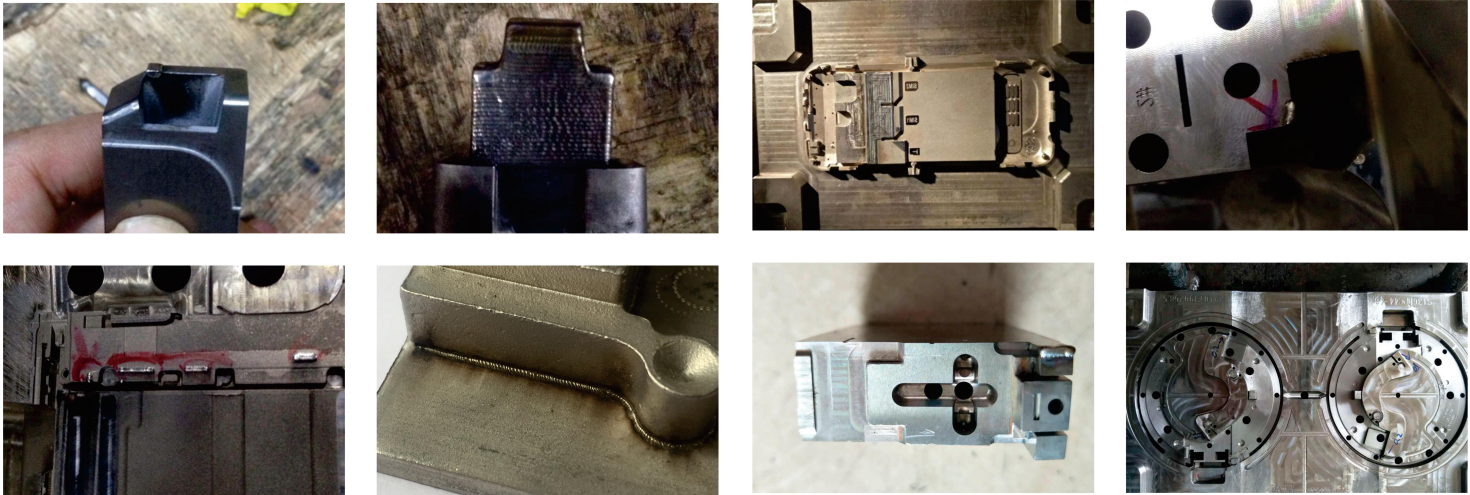

Application

Suitable for large mold repair welding, mobile phone communications, jewelry crafts, electronic components, clocks, sensors, precision machinery, hardware, gas and vehicle parts, etc., various metals and alloys.

Production Facility

Mold repair fiber laser welding

Mold repair fiber laser welding