- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

2024 best Handheld Fiber Laser Welding Machine for Industrial field

SAN LASER's 2024 best handheld fiber laser welding machine is a new generation of laser welding equipment. It is a non-contact welding. The operation process does not require pressure. The handheld fiber laser welding machine replaces the previous argon arc welding. It is flexible and convenient, and the welding distance is long. It also makes laser welding operations outdoors possible.

Handheld welding is mainly used for laser welding of long-distance and large workpieces. It overcomes the limitations of the workbench travel space and has a small heat-affected area during welding. It can be a perfect replacement for welding of thin stainless steel plates, iron plates, galvanized plates and other metal materials. Traditional argon arc welding.

Handheld continuous laser welding: It is mainly composed of laser, welding system, handheld laser gun and cooling system. It is a new generation of semiconductor-pumped pulse fiber laser in the near-infrared spectrum range. It has good beam quality, fiber output and high electro-optical conversion. Efficiency and other characteristics, it is mainly used for welding thin-walled materials and rapid welding. The welding process is of heat conduction type, that is, laser radiation heats the surface of the workpiece, and the surface heat diffuses to the interior through heat conduction. By controlling the width, energy, peak power and repetition frequency of the laser pulse and other parameters to melt the workpiece and form a specific molten pool.

l Total installed machine power (MAX): 2.5-5KW;

l Equipment utilization rate: ≥95%;

l Product qualification rate: ≥99.5%;

l Equipment failure rate: ≤ 2%.

Adopt our handheld laser welder to create firm joints higher than its substrate, far surpassing other ordinary welding machines. You can benefit from continuous welding, smooth seam and no follow-up polishing procedures.

Multi-welding modes to solve diverse welding challenges

Maximum welding capability powered with multi-welding modes

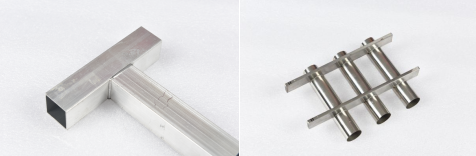

Non-contact welding makes welding hard-to-reach places easy. Diversified welding nozzles satisfy all kinds of welding requirements, such as spot welding, butt welding, overlap welding, vertical welding, flat filet welding, internal and external filet welding. The welding of workpieces with complex seams or irregular shapes becomes so easy

v Various angle nozzles can be configured to meet the welding needs of different products.

v The shape is lightweight and adopts body engineering design method to provide a comfortable grip;

v It is easy to control with one hand, and the operation is simple and easy to use.

v The smart internal design and good interactive control system expand the tolerance range of processed parts and weld width, solve the disadvantage of small light spots, and achieve better weld formation.

Safety clip ensures operation safety

Worry-free laser welding

A safety clip equipped on the laser welder improves operation safety during work. The laser will not go out from the laser gun unless the welding gun touches the metal, thus your safety can be fully guaranteed.

Long-distance welding makes large object welding easily

Custom fiber cable length adapts to wide working scenarios

Set with movable pulleys, you could overcome the limits of fixed workstation and freely move your welding station to wide working environment scenarios. Custom fiber allows you to weld large objects and hard-to-reach places.

Simple operation saves your costs on labor

Even a green hand could get the swing of it quickly

Our handheld laser welder requires no senior technician, even a green hand could get started with laser welding in a few hours. It’s a good choice for curb labor expenses.

In the industrial field, handheld laser welding machines are widely used. Handheld laser welding machines can weld various metal materials. For metal processing, the welding efficiency has been improved by at least 60%, such as in automobile manufacturing, aerospace manufacturing, mold repair, and hardware processing. , sheet metal processing and other fields, laser welding applications are becoming more and more common

1. Metal welding: Handheld laser welding machine can be used for welding metal materials, such as steel, aluminum alloy, copper, etc. It can achieve high-precision, high-quality welding without using traditional welding materials, reducing pollution and loss during the welding process.

2. Electronic equipment manufacturing: Handheld laser welding machines can be used in the manufacturing and repair of electronic equipment. It can weld tiny electronic components, such as resistors, capacitors, etc. on circuit boards. Because laser welding has the characteristics of high precision and high speed, it can improve production efficiency and product quality.

3. Precision instrument manufacturing: Handheld laser welding machines can be used to manufacture precision instruments, such as optical instruments, medical equipment, etc. Laser welding can achieve non-contact welding, avoid vibration and thermal deformation problems that may be caused by traditional welding methods, and ensure the accuracy and stability of the instrument.

4. Automobile manufacturing and repair: Handheld laser welding machines can be used in automobile manufacturing and repair fields. It can weld automobile parts such as body, engine parts, etc. Laser welding can achieve high-strength welding, improving the safety and durability of cars.

5. Pipe welding: Handheld laser welding machine can be used for pipe welding. It can weld pipes of various materials, such as stainless steel pipes, copper pipes, etc. Laser welding can achieve seamless welding and improve the sealing and pressure resistance of the pipeline.

6. Food processing: Handheld laser welding machines can be used in the food processing industry. It can weld food processing equipment such as stainless steel containers, pipes, etc. Laser welding can achieve pollution-free welding and ensure food safety and hygiene.

In short, handheld laser welding machines have a wide range of applications and can be used for welding various materials, such as metals, plastics, ceramics, etc. It can achieve high-precision and high-quality welding, improving production efficiency and product quality. With the continuous development of technology, the application fields of handheld laser welding machines will continue to expand.

Applications

Applications