QCW/Fiber Mould laser welding machine with crane

Get a free quote1. Fiber laser and QCW laser can be selected, with stable and reliable beams

2. Equipped with a dedicated chiller, which can meet long-term welding requirements and provide better stability;

3. Equipped with a three-dimensional load-bearing workbench base with electric lifting, the workbench moves using precision ball screws and high-precision straight guide rails, which are light and flexible, with precise positioning and a load-bearing capacity of 50 kg;

4. Equipped with a gas protection system, which effectively protects the product from argon gas protection during welding, maintains the product's true color and ensures welding quality

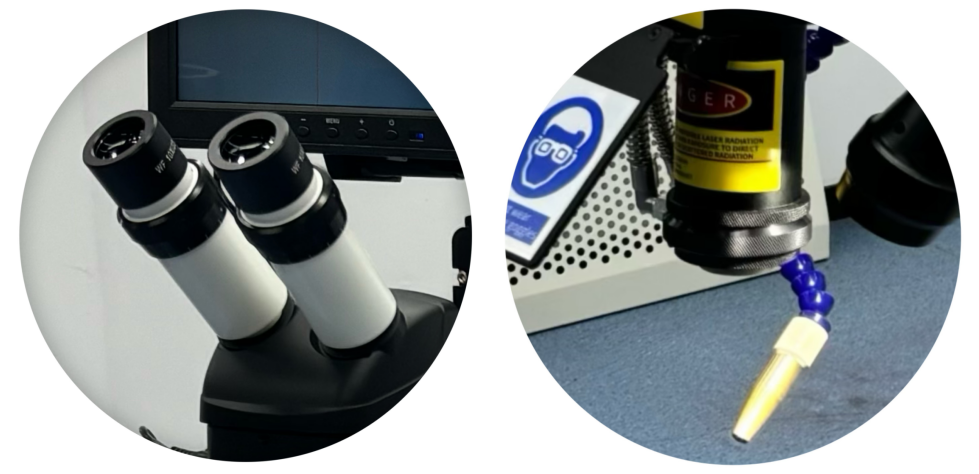

1. Observation system and lighting

·Observe the welding process through a stereo microscope (with 10x eyepiece).

·Water-cooled focusing lens

2. Controller and Operation

·7-inch high-contrast widescreen. Full menu touch screen operation.

·Knob control, parameter adjustment, easy operation

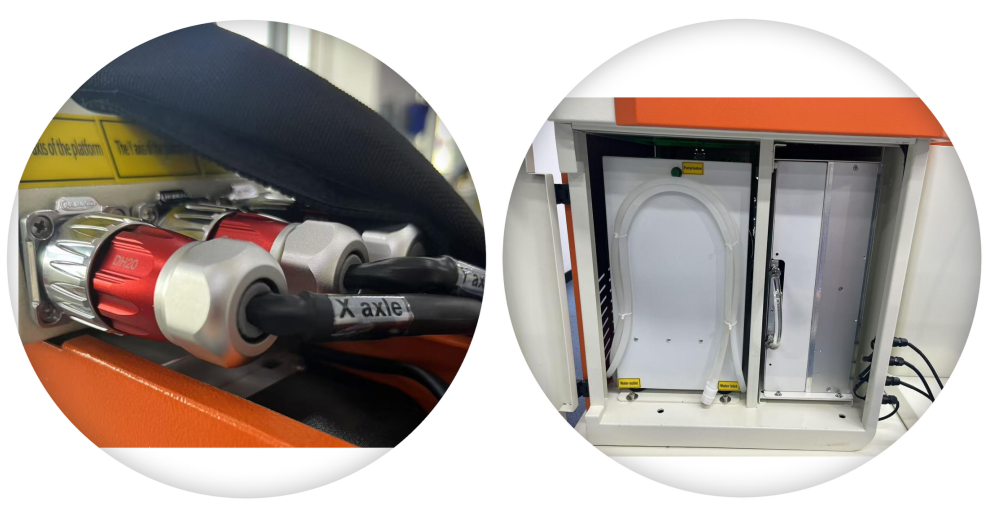

3.Cardan shaft control and XYZ - Axis system

·The end of the arm is equipped with a universal shaft connector, which can manually control the welding head to rotate 360° to any angle and fix it, and the xyz axis can be electrically controlled to achieve a larger welding range. At the same time, with the help of an electric handle, the forward and backward, up and down movement of the robot arm can be fixed at the desired position to complete the process operation.

·An optional three-axis motion system controlled by stepper motors is available. The X, Y and Z axes offer motion capabilities with strokes of 150 mm, 150 mm and 100 mm respectively. The system can be integrated with a rotary device (optional) for peripheral welding of cylindrical parts as the rotary axis R axis

4.XYZ - Axis Three-axis joystick

·Three-axis joystick control axis system is used to accurately position the laser head and move it during operation

5. Aviation plug and split cabinet

·Upgraded aviation plug, better quality and more stable.

·Laser and water cooler split design, easiermaintenance.

6. Shielding gas nozzle

·The shielding gas used during welding is connected to the system via the machine body. The shielding gas is delivered in an integrated manner in the system and to the welding area. Since the hose can be positioned directly next to the laser head, the shielding gas can be optimally directed to the processing area.

7. Limit switch

·During manual operation of the axis via joystick control, mechanical switches automatically limit the movement when the axis reaches the edge within the travel distance and ensure safe operation.

Video

Technical Parameter

Model | QCW-150W | QCW-300W | FIBER-1500W |

Maximum laser power | 150W | 300W | 1500W |

Laser wavelength | 1080±10nm | ||

Laser fiber length | 10M | ||

Laser frequency | 1-30Hz | 1-30HZ | 1-25HZ |

Pulse Width | 1-20Ms | 1-20Ms | 1-60MS |

Light spot adjustment range | 0.2-3mm | 0.2-5mm | 0.2-5mm |

Aiming and positioning | Microscope (optional camera system) | ||

Chiller cooling power | 0.6P | 0.6P | CW1500 |

Rated power | 2.5KW | 3KW | 7KW |

Power demand | 220V±5V 50Hz/60A | ||

Three-dimensional load-bearing workbench | 50kg | ||

Overall dimensions/net weight | host:1650*920*1150mm | ||

| Three-dimensional load-bearing workbench:600*450*600mm | |||

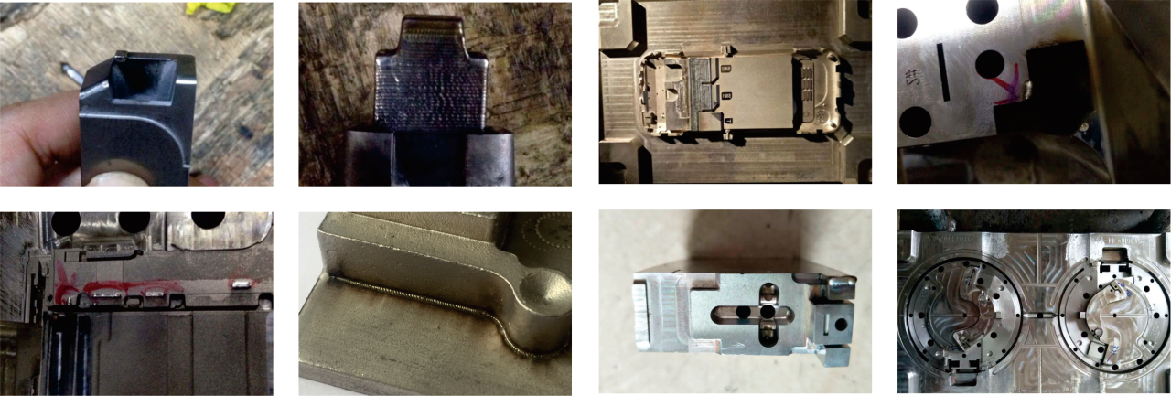

Application

Suitable for large mold repair welding, mobile phone communications, jewelry crafts, electronic components, clocks, sensors, precision machinery, hardware, gas and automobile parts, etc., various metals and alloys.

Production Facility

QCW/Fiber Mould laser welding machine with crane

QCW/Fiber Mould laser welding machine with crane