- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Popular Science: What are the differences between three-axis, four-axis, and five-axis CNC machining machines?

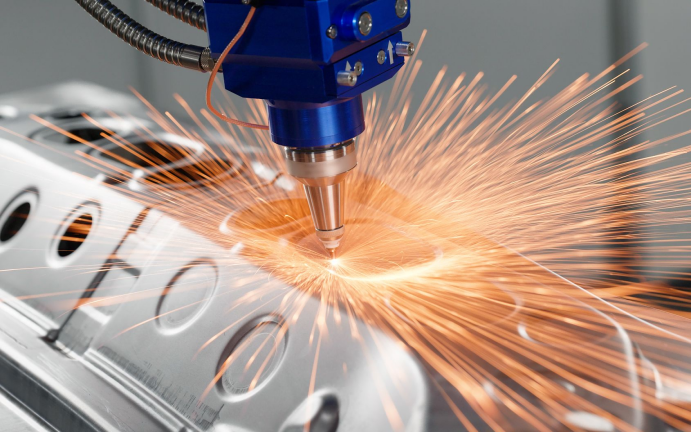

With the rapid development of the manufacturing industry, automation technology has emerged in various fields, and the demand for automated laser cutting machines has continued to expand. We often see that one of the types of CNC machines is classified as three-axis, four-axis, and five-axis. So what is the difference between them?

3-axis CNC machining is the simplest and most common machining method. CNC machines can cut into workpieces from one side to the other, from front to back, and up and down, but the fixed workbench cannot move freely. Suitable for low-cost and fast production of simple parts with basic geometric shapes.

Compared with 3-axis machines,4-axis machines have an extra degree of freedom through rotational motion, which can be processed along the contour of the workpiece, providing more possibilities for the processing of complex workpieces, more precise processing, and most work only requires one clamping, saving time, but the operation is more complicated and the processing cost is higher.

5-axis machining is the most advanced method for manufacturing complex precision metal parts in the workshop. It can be rotated during processing, and multiple planes of the parts can be processed. It can perform precise 3D processing and process curved geometric shapes. It is widely used in the fields of aerospace and automobile manufacturing.

Related product links

Cutter News

Cutter News