- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

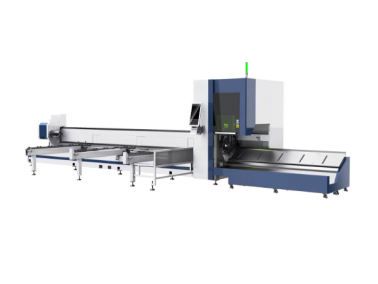

Stainless steel laser pipe cutting machine: precise cutting, the best choice in the industry!

In modern engineering and manufacturing fields, stainless steel is widely used due to its corrosion resistance, aesthetics, and high strength. Stainless steel pipes are widely used in modern manufacturing industries such as the construction industry, automobile industry, etc. In order to meet the growing demand for stainless steel products, stainless steel laser pipe cutting machines came into being. The stainless steel laser pipe cutting machine uses high-energy laser beams to efficiently and precisely process stainless steel pipes of various sizes and shapes, providing high-quality, high-precision solutions for all works.

1. Precise cutting, high quality casting

Laser pipe cutting machines offer excellent cutting accuracy and customization capabilities. With the help of a highly integrated laser system, it can achieve micron-level precision cutting, keep the cutting edge smooth, and avoid processing defects that may be caused by traditional cutting methods. Accuracy not only ensures product quality, but also improves product reliability and service life.

2. Efficient production and enhanced competitiveness

The stainless steel laser pipe cutting machine uses high-energy laser beam, which has fast working speed and high production efficiency. Compared with traditional mechanical cutting, it can not only greatly shorten the production cycle, but also save labor costs. A high-efficiency production model enables companies to respond to market demand more quickly and locally, seize market share in advance, and gain competitive advantages for companies.

3. Customized production to meet diversified needs

The flexibility of the laser pipe cutting machine allows it to customize stainless steel products of various shapes and specifications according to customer needs. Whether it is customized furniture, kitchen equipment, or special-shaped parts, stainless steel laser pipe cutting machines can easily do the job and provide customers with products that meet individual needs.

4. Environmental protection and energy saving, leading green manufacturing

The stainless steel laser pipe cutting machine uses non-contact cutting, which consumes cutting tools, reducing energy consumption and material waste. Compared with traditional cutting methods, it does not produce loss or waste water, and is in line with the concept of green production in modern manufacturing.

The emergence of stainless steel laser pipe cutting machines not only improves the processing accuracy of stainless steel products, but also provides a more efficient, environmentally friendly and economical production method. It is not only a powerful assistant in modern manufacturing, but also promotes the stainless steel industry. With the continuous advancement of science and technology, the stainless steel laser pipe cutting machine will play its role in a wider range of fields and lead the future manufacturing industry to a higher level.

Related product links

Cutter News

Cutter News