- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

6 core components of fiber laser cutting machine!

Basic knowledge of laser cutting machine: You must read these six core components

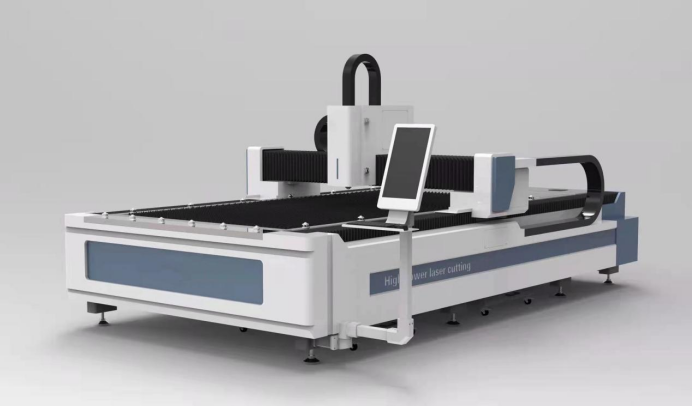

In metal processing, fiber laser cutting machines, with their advantages of high efficiency and high quality, have gradually replaced traditional processes and become a powerful tool in the metal processing industry.

But even if they are all called fiber laser cutting machines, the processing efficiency and effects of different equipment inside will be very different. For fiber laser cutting machines, you must look at the six core accessories when purchasing.

1. Laser Source

Laser source is the "power source" with laser equipment as its core. Just like a car engine, it is also the most expensive component in fiber laser cutting machines. At present, well-known Chinese laser brands such as Raycus and Max are gradually recognized by the market for their high cost performance. They are also our long-term suppliers.

2. Cutting head

The cutting head is the laser output device of the fiber laser cutting machine. It consists of a nozzle, focusing lens and focus tracking system. The cutting head of the laser cutting machine will move according to the set cutting trajectory, but under different materials, different thicknesses, and different cu

3. CNC system

The control system is the dominant operating system of the fiber laser cutting machine. It mainly controls the machine tool to realize the movement of the X, Y, and Z axes, and also controls the output power of the laser. The quality of the laser cutting machine brand determines the operational performance stability of the fiber laser cutting machine. Through accurate control of the software, the accuracy and cutting effect can be effectively improved.

4. Motor

The motor of the laser cutting machine is the core component of the motion system. The performance of the motor directly affects the product processing effect and production efficiency. Currently, commonly used motors include stepper motors and servo motors. According to the industry type and product type of the processing object, the configuration Suitable motor

Stepper motor: fast starting speed, sensitive response, suitable for engraving and less demanding cutting. The price is lower. There are many brands of stepper motors with different performances.

Servo motor: fast movement speed, smooth movement, high load, stable performance; processed products have smooth edges and fast cutting speed; high price, suitable for industries and products with high processing requirements.

5. Machine tools

Fiber laser cutting machines have very high requirements on machine tool stability. High-precision and high-stability machine tools are conducive to improving the accuracy of laser cutting. At present, the mainstream machine tools on the market include gantry type, cantilever type, beam type, etc. Different machine tools have different functions. For example, beam type machine tools are mainly used for material cutting by large manufacturers. There are also models used in specific fields, such as three-dimensional fiber laser cutting. , mainly used in the automotive industry, etc.

6. Laser lenses

Laser lenses are mostly used in the entire fiber laser cutting equipment. Many optical devices contain laser lenses. Different lenses have different functions, including fully reflective lenses, semi-reflective lenses, focusing lenses, etc.

The quality of the lens directly affects the output power of the laser, and also affects the performance of the entire machine. Similarly, lenses are divided into domestic and imported lenses. The lifespan and cutting effect of domestic lenses are not as good as imported lenses, but their prices are much cheaper than imported lenses.

Cutter News

Cutter News