- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Why are the protective lenses often burned when using laser welding machines?

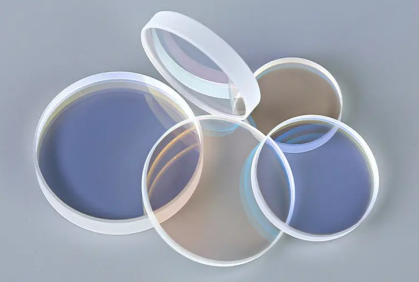

The protective lens of the laser welding machine is consumable, so it needs to be replaced regularly. However, due to the influence of the process/technique/setup, etc., it may cause damage by slag retrieval. In rare cases, abnormal laser light output and other factors may also easily lead to the protective lens of the laser welding machine equipment burned out when being used. What causes the protective lens of the laser welding machine to burn out and how to deal with it?

Analysis of the causes of burnt protective lenses:

To prevent improper use of laser welding machine equipment, which often causes the protective lens to be burned out, we can extend the life of the protective lens of the laser welding machine from the following aspects.

1. First consider whether the auxiliary gas we blow is pure. Whether the pressure meets the standards. If you are blowing air, you need to check the quality of the compressed air.

2. Check whether the optical path is deflected during the laser emission process, and whether other lenses are damaged during the operation.

3. Check whether the hole diameter of the applicable nozzle is too large.

4、Check whether the timing configuration of the software for punching and blowing is reasonable.

How to correctly reduce the loss of protective lenses:

1. Increase the air pressure appropriately. Normally, the flow rate is not less than 15 and the pressure is not less than 4. It is recommended to use an oxygen pressure gauge not less than 2 kg.

2. When welding, try to weld the welding gun and the plate at a 45° angle, not vertically

3. Set the parameters as slowly as possible, such as gas on/off delay 200-500ms, light on/off power 20%, light on/off gradual time 200-300ms, and cannot be set to 0

4. When welding aluminum and galvanized sheets, this material will damage the lens more easily than other materials, so the minimum power should be used for welding

5. The quality of protective glasses also determines their durability. It is recommended to use original lenses

6. Under high power, compared with low power, the loss of the lens will increase, which is an uncontrollable range

7. When none of the above can be dealt with, you can replace the F200 focusing lens + lengthened wide scale tube to reduce splashing

The above is an analysis of the reasons for the burnout of the protective lens of the laser welding machine and a brief introduction to reducing the loss of the protective lens. When using laser welding equipment, some minor faults often occur due to improper operation or lack of attention to maintenance. Therefore, it is recommended that customers use When using laser welding equipment, it is best to undergo professional training and perform routine maintenance on the laser welding equipment.

Cutter News

Cutter News