- No.609, Centre Of Huijin Nanxiang, Yinxiang Road, Nanxiang Town, Jiading District, Shanghai, China

- sherry@sanmachines.com

- +86-18616767021

Practical Methods to Improve the Efficiency of Laser Cutting Machines

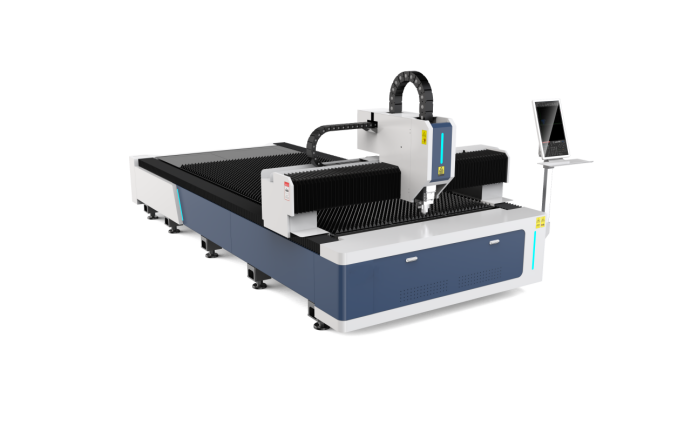

Fiber laser cutting machines have now become an indispensable tool in the field of metal cutting, and are rapidly replacing traditional metal processing methods. Due to the rapid development of the economy, the order volume of metal processing companies has increased rapidly, and the workload of fiber laser equipment has increased day by day. In order to ensure that orders are delivered on time, it is very important to improve laser cutting efficiency.

So, in the actual metal processing process, how can we achieve a significant improvement in laser cutting efficiency? Please let us introduce you to the functions that need to be paid attention to when using the two laser cutting equipment.

1. Automatic focus function

When laser equipment cuts different materials, it requires the focus of the laser beam to focus on different positions of the workpiece cross section. Accurately adjusting the focus position of the light spot is a key step in cutting. The method of automatic focusing is to install a variable-curvature reflector before the beam enters the focusing mirror. By changing the curvature of the reflector, the divergence angle of the reflected beam is changed, thereby changing the focus position and achieving automatic focusing. Early fiber laser cutting machines generally used manual focusing. The automatic focusing function can save a lot of time and improve laser cutting efficiency.

2. Automatic edge finding function

The automatic edge-finding function is also very important for improving laser cutting efficiency. It can sense the inclination angle and origin of the sheet to be processed, and then automatically adjust the cutting process to find the best positioning angle and position, thereby achieving fast and accurate cutting and avoiding Material waste. With the automatic edge-finding function of the laser cutting machine, the time required to repeatedly adjust the workpiece can be greatly reduced. After all, it is not easy to repeatedly move a workpiece weighing hundreds of kilograms on the cutting workbench, thus greatly improving the efficiency of the entire laser cutting production.

Cutter News

Cutter News